The Grade Guide: 400 Series Martensitic Stainless Steel

Stainless steel comes in a variety of grades and compositions. It is essential to consider your final application for the material in order to select the correct type and grade of stainless steel.

The Main Grades of Stainless Steel

Austenitic, ferritic, martensitic, duplex, and precipitation-hardening are the main types of stainless-steel alloys. Their differences are based on their distinct microscopic crystalline structures, each of which lends the steel a specific metallurgical profile.

The most widely used stainless steel is austenitic, with the 300 series being the most popular grade. At Certified Grinding & Machine, 303 Stainless Steel is our most popular grade; our second most popular grade is 416, martensitic stainless steel.

The Specifics of 400 Stainless

Class 400 Stainless Steel is a martensitic, iron and chromium (12%-17%) based alloy that has limited to moderate corrosion-resistance, and is magnetic.

One of the key differences between 400 and 300 series stainless steels is that 400 series stainless steels can be hardened and tempered through heat treating. The 400 series also has limited formability and weldability. The benefits of 300 series stainless steels are its corrosion resistance and its high ductility. The benefits of 400 series is its increased hardness capability through heat treatment and its strength.

The most common martensitic stainless steels are types 410, 416, 420, and 440. (Although 630 is considered a martensitic stainless steel, it will not be addressed in this blog.) Although related, these alloys differ in areas like chemical composition, material capabilities, and cost.

Type 416 Stainless Steel

The most commonly used martensitic stainless steel at Certified Grinding & Machine is type 416 Stainless Steel. It can be ordered in the annealed condition, Condition T with an RC of 26-32, and Condition H with and RC of 32-38.

416 stainless steel is a free machining grade due to the addition of sulfur. It can be easily turned, tapped, broached, drilled, reamed, threaded, milled, and ground.

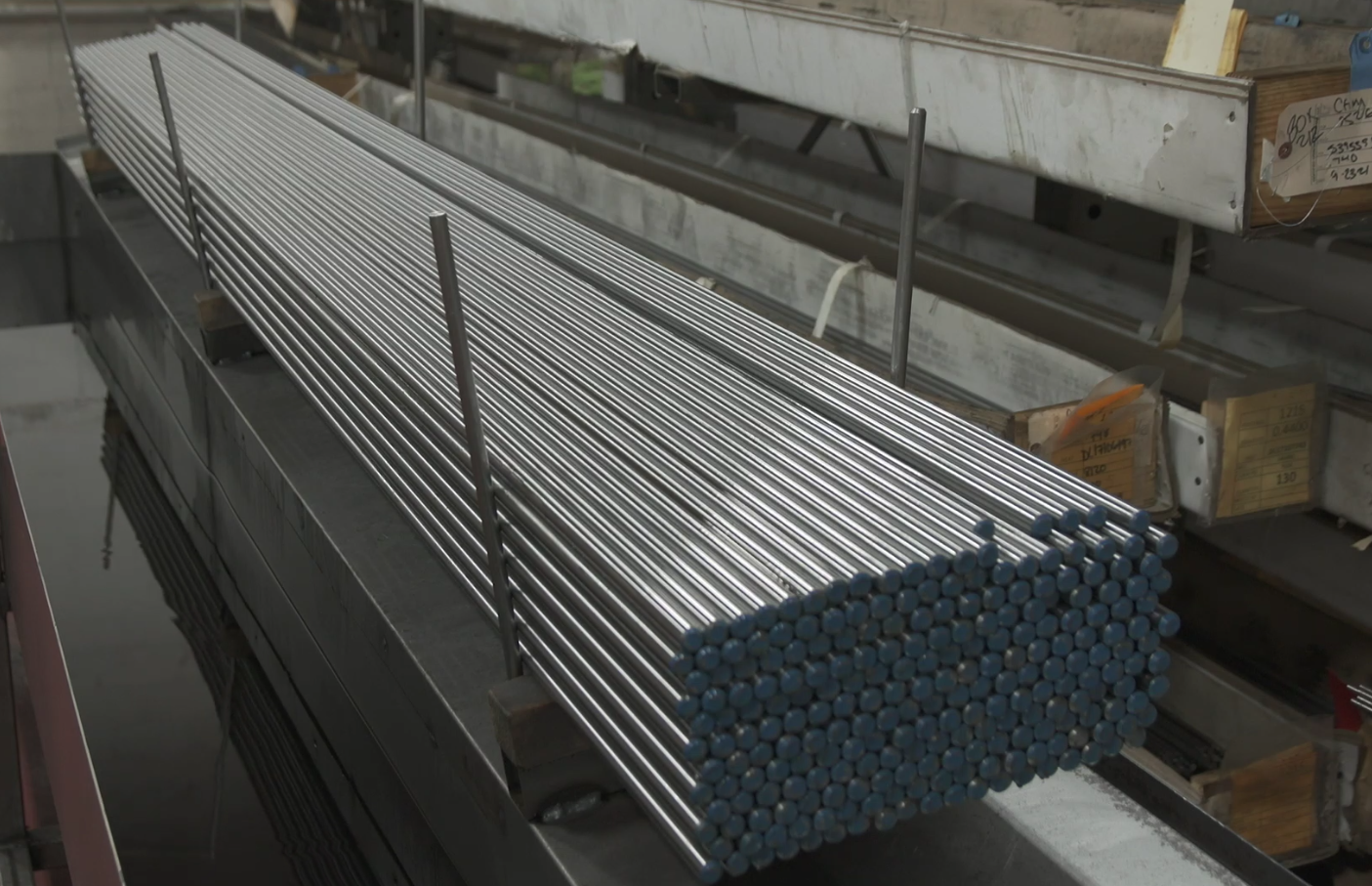

Certified Grinding & Machine maintains an extensive inventory of 416 annealed barstock, and limited inventories of 416T and 416H bars. In our experience, 416 is the least expensive of the martensitic stainless steels.

We primarily stock 416 stainless steel barstock manufactured by Swiss Steel. The unique production process—developed exclusively by Ugitech—results in a product that delivers superior productivity, tool life and consistency, and improves the surface finish on all types of machined parts.

Type 420 Stainless Steel

420 is another of the less common grades of martensitic stainless steels. It generally has a higher chromium content than 416 and therefore exhibits better corrosion resistance. Due to its higher carbon content, 420 has much higher strength and hardness than 410 stainless steel.

Type 440 Stainless Steel

Type 440 stainless steel can be purchased in various states including 440A, 440B, and 440C. By far, the most popular of these grades is 440C. 440C stainless steel is a high carbon, high strength metal with good hardness and wear resistance. It is capable of attaining the highest strength and wear resistance of all of the stainless alloys especially when heat treated to an RC of 60. 440C is used to produce high quality knife blades and many surgical instruments.

At Certified Grinding & Machine, we have the experience and knowledge to help you select the correct grade of stainless steel for your part. Our team will work with you to understand your final application and troubleshoot any process issues you may encounter.

Have questions about which stainless steel grade is right for you? Contact us today.